Welding and Cutting Manufacturer |

info@wxfengwei.com |

|

|

|

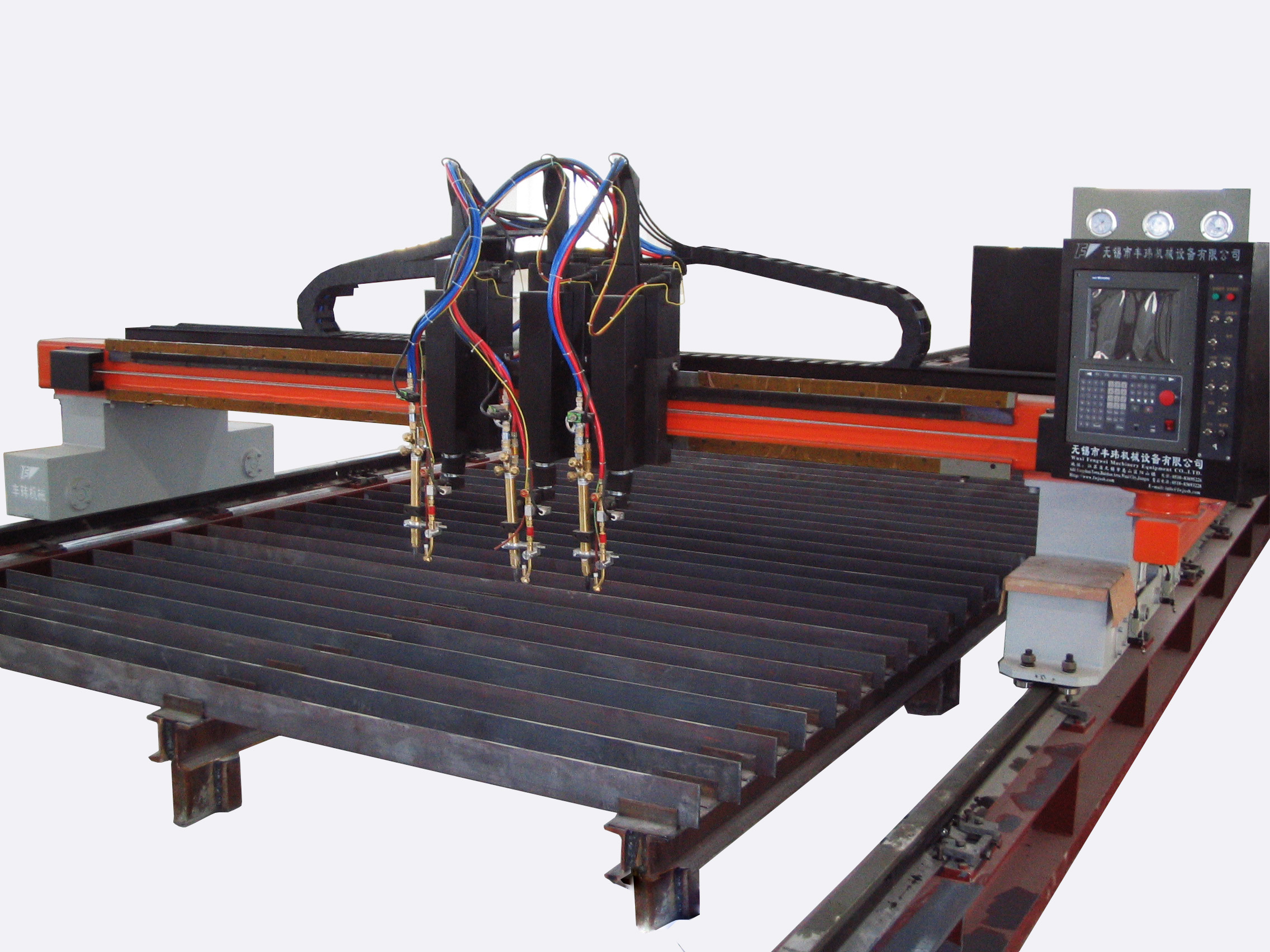

How to protect electrode nozzle in CNC Plasma Cutting Equipment? |

How to use the cutting nozzle of CNC plasma cutting machine efficiently so that it is not easy to break? I believe that this is a very common problem that many users are quite concerned about. In the use of CNC plasma cutting machines, the use of cutting nozzles is an important factor directly related to the cutting cost. Let's analyze the factors that help to extend lifetime of electrode nozzle in operating plasma cutting machines. Please review below: |

|

1. Lesson perforation during operation of CNC Plasma Cutting Equipment. While in perforation, it causes molten steel back-splash that can damage the nozzle. This is one of the most important reasons to cause cutting nozzle damage. If you must pierce and cut, it is recommended to use a drill to prepare the hole in perforation, and then start cutting at the pre-drilled hole. |

|

2. Try to strictly cut within the limit of normal pre-requested thickness range of the machine, rather than reach or over the limit of cutting thickness. The well-preserved cutting thickness range is generally 60% of the maximum cutting thickness marked by the manufacturer. For instance, the domestic 100A plasma cutting machine endures the maximum cutting thickness marked by the manufacturer is generally 32mm, but the most cost-effective way is to cut thickness of 15-20mm only. Therefore, try to cut within max thickness range to best protect and extend lifetime of the electrode nozzle. |

|

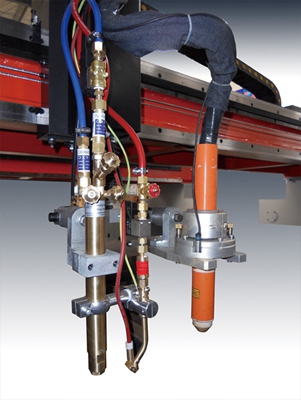

3. The distance between the cutting nozzle and the steel plate should be kept as constant as possible, generally about 3-8mm. If it is too far, not only the power consumption is too large, but the cutting penetration ability will be reduced, and the electrode is relatively consumed, which reduces the service life of the electrode. If it is too close, then too easily break the noddle and expensive to replace the nozzle, due to two reasons. The nozzle is easily burned up, and the air pressure adjustment is also very critical. |

Besides above all, the service life of the plasma electrode nozzle is also related to other factors, such as the level of the input voltage, the quality of the electrode itself, the quality of the plasma cutting machine and the integrity of the equipment, the quality of the plasma torch, the user Experience, etc., However, the most important thing is the above three points, pay attention to these three points, the service life of the electrode nozzle will be greatly improved. |

+86 139 1534 9938/info@wxfengwei.com |